UTM-E100/E200/E300 Computer Controlled Electronic Universal Testing Machine

Video Demonstration

Product Features & Applications

Product Features:

- The main machine adopts a rigid floor-standing gantry frame structure, which is composed of an upper crossbeam, a movable crossbeam and a workbench connected by columns and ball screws, ensuring stability and reliability.

- The movable crossbeam is processed from a single casting, which ensures it can bear sufficient force without deformation.

- It can conduct both tensile and compression tests simultaneously, with the upper part serving as the tensile test space and the lower part as the compression test space.

- Driven by a servo motor, it is equipped with a high-precision sensor, a dedicated independent controller and measurement and control software, enabling precise control of the equipment.

- Equipped with a magnetic handheld control box, facilitating users to operate the equipment from a distance.

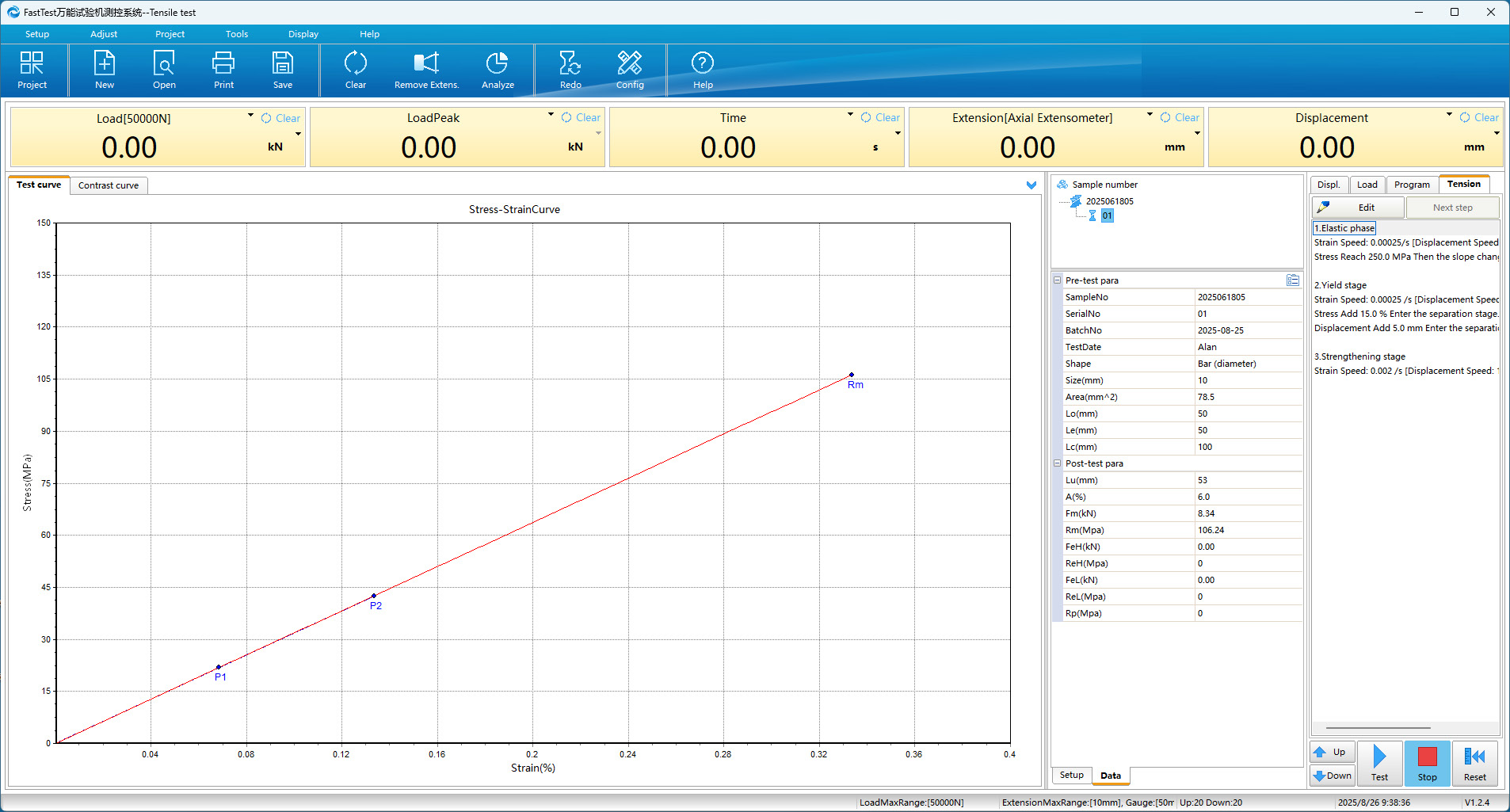

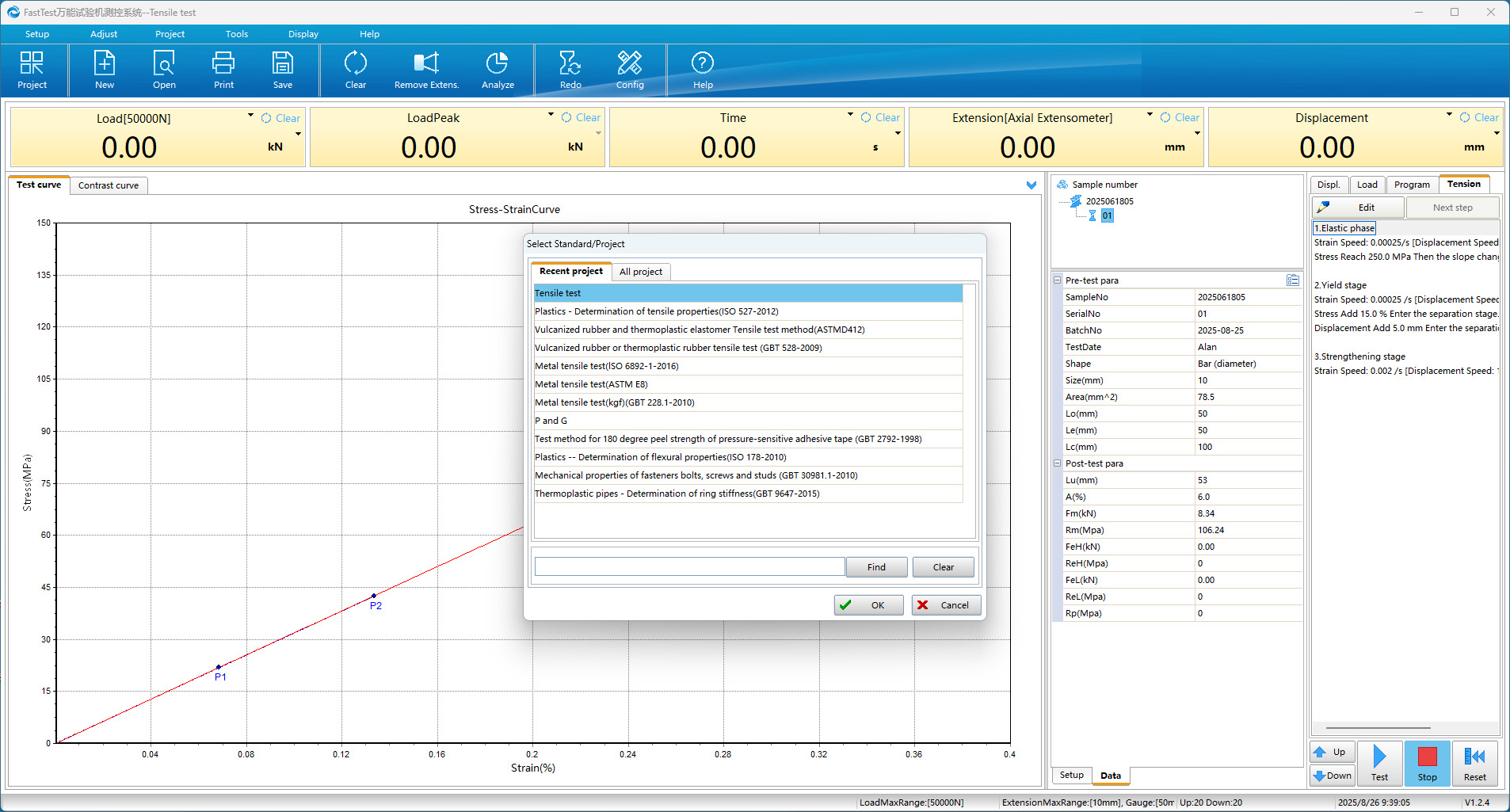

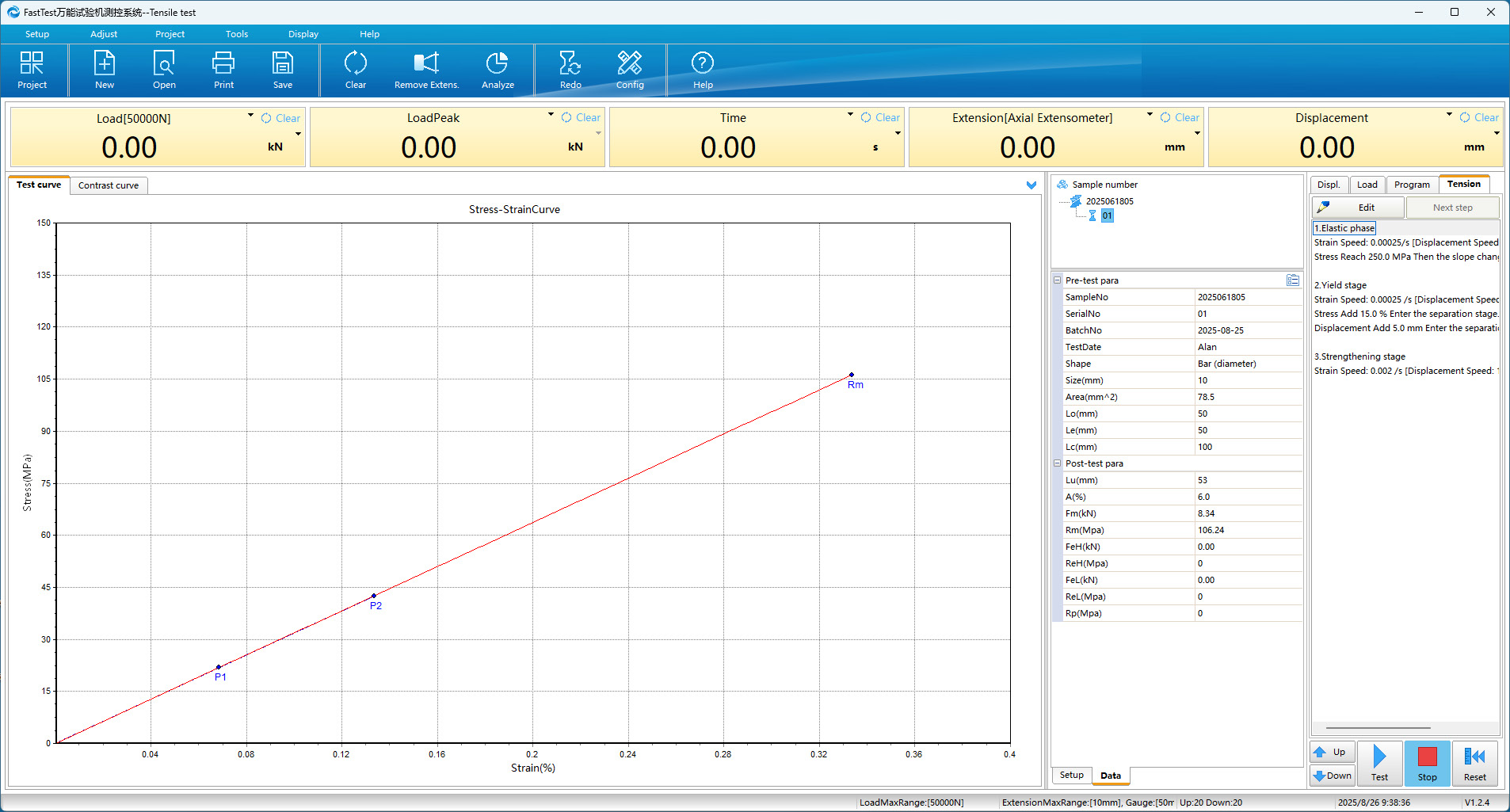

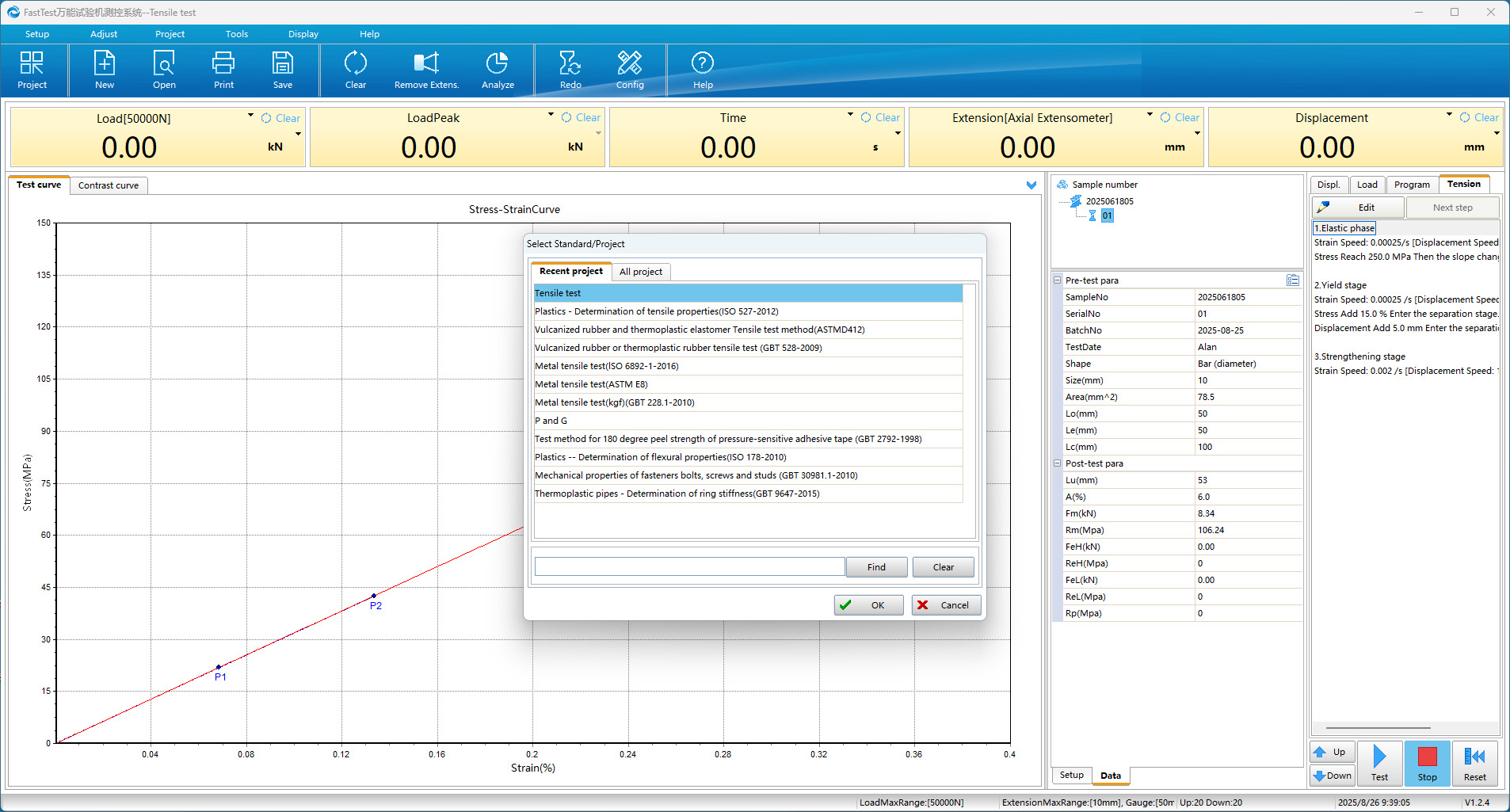

- The dedicated software has multiple functions to meet the needs of different users. It also features a modular and open design. In addition to providing common standards such as GB, ASTM, DIN, ISO and JIS, users can design calculation formulas according to their own requirements.

- The software can generate real-time curves in multiple modes, including force-time, stress-time, strain-time, displacement-time, etc.

- The software can automatically calculate parameters such as maximum force, average force, maximum deformation, tensile strength and yield strength.

- It provides customizable test report templates for users, supporting report export in multiple formats: Word, PDF and Excel.

- The software is compatible with multiple Windows operating systems: Windows 7, Windows 10 and Windows 11

- Maximum test force: 100kN

- Test speed range: 0.001 – 500mm/min

- Multiple units are available

- Force units:KN、N、kgf、lbf

- Displacement units:mm、cm、dm、m、in、ft、mil

- It can automatically return to the initial position after the test is completed.

- Equipped with multiple protection devices, including mechanical travel switches, emergency stop switches and overload protection.

- Standard tensile and compression fixtures are provided, and custom fixtures can be made according to user needs.

- It complies with the following execution standards: GB/T 2611, GB/T 16491, GB/T 16825, GB/T 228, ISO 527, ASTM D3574, DIN 53357, JIS K6854, etc

Product Applications:

- Metal materials field

- Raw material quality control

- Processing technology verification

- Finished product performance testing

- Non-metallic materials field

- Testing of plastic and rubber products

- Testing of textiles and leather products

- Testing of paper and packaging materials

- Construction and building materials field

- Building materials testing

- Scientific research and education field

- Scientific research experiments

- Teaching demonstrations

Technical Specifications

|

Name |

Computer Controlled Electronic Universal Testing Machine |

||

|

Model |

UTM-E100 |

UTM-E200 |

UTM-E300 |

|

Max Load |

100KN |

200KN |

300KN |

|

Load Accuracy |

Grade 1 (Optional Grade 0.5) |

||

|

Testing Range |

2%~100%F.S (Optional 0.4%~100%F.S) |

||

|

Load Resolution |

1/500000FS |

||

|

Test Control Mode |

3 closed loop control, stress, strain and displacement |

||

|

Deformation Measuring Range |

0.2%~100%FS |

||

|

Deformation Accuracy |

≤±0.5% |

≤±1% |

|

|

Displacement Accuracy |

≤±0.5% |

≤±1% |

|

|

Displacement Resolution |

0.01mm |

||

|

Control Mode |

Force closed loop control, deformation closed loop control, displacement closed loop control | ||

|

Force Control Controls The Speed Range |

0.001%~5% FS/s |

||

|

Constant Force Control Accuracy |

When the rate is < 0.05%FS/s, it is within ±2% of the set value; When the rate is ≥0.05%FS/s, it is within ±0.5% of the set value | ||

|

Deformation Control Controls Speed Range |

0.001%~5%FS/s |

||

|

Constant Deformation Control Accuracy |

When the rate is < 0.05%FS/s, it is within ±2% of the set value;

When the rate is ≥0.05%FS/s, it is within ±0.5% of the set value |

||

|

Max. Tensile Testing Space |

650mm |

550mm |

|

|

Max. Compression Testing Space |

550mm |

||

|

Test Width |

400mm |

600mm |

500mm |

|

Crosshead Speed Range |

0.001-500mm/min |

0.001~180mm/min |

|

|

Overall Dimensions (L*W*H) |

800*500*1941mm |

1045*650*2300mm |

1050*650*2300mm |

|

Power Supply |

1P 220V±10%, 50-60HZ,1KW |

1P 220V±10%, 50-60HZ,2.5KW |

|

|

N.W. |

About 500kg |

About 1500kg |

|

Standard Configuration

| Name | Qty |

| Host Frame | 1 set |

| AC Servo Control System | 1 set |

| Ball Screw | 1 set |

| Synchronous Pulley | 1 set |

| Synchro Belt | 1 set |

| 100kN Load Cell | 1 set |

| Control System | 1 set |

| English Operation Software | 1 set |

| Handheld Unit Controller | 1 set |

| HP Computer | 1 set |

| HP Printer | 1 set |

| Manual Wedge Tensile Grip | 1 set |

| Flat Jaw :0-7mm | 1 set |

| Round Jaw :Φ4-9mm;Φ9-14mm | 1 set |

| Φ100mm Compression Test Grip | 1 set |

| Instruction Manual | 1 copy |

| Certificate of Qualification | 1 copy |

| Calibration Certificate | 1 copy |

| Warranty Card | 1 copy |

Optional Configuration

| 3-point Bending Fixture |

| Electronic Extensometer |

| USA Epsilon Extensometer |

| Large Deformation Extensometer |

| Protective doors |

| Fixtures of other models |

최신 제품

최신 정밀 측정 솔루션

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- 그래니트 설정 도구

- 그래니트 설정 도구

- iVibra-6380 3축 진동 테스터

- MS602L Electronic Balance

- MS2003GH 전자 저울

- MS63B Electronic Balance

마지막으로 업데이트되었습니다: 2026-02-14

모든 신제품 보기