UHT-100 Ultrasonic Hardness Tester

Product Features & Applications

Product Features:

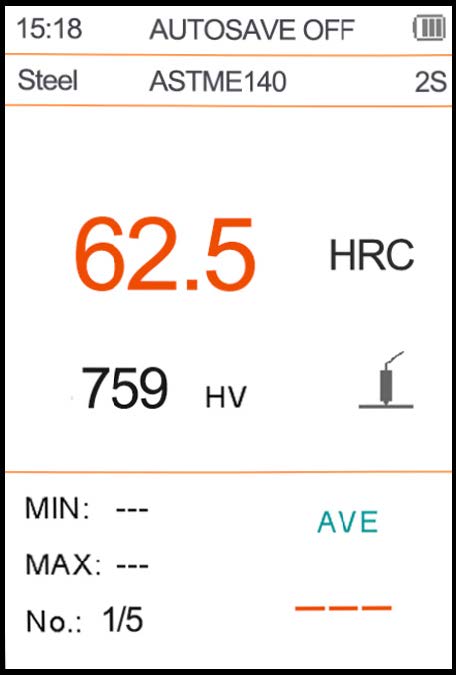

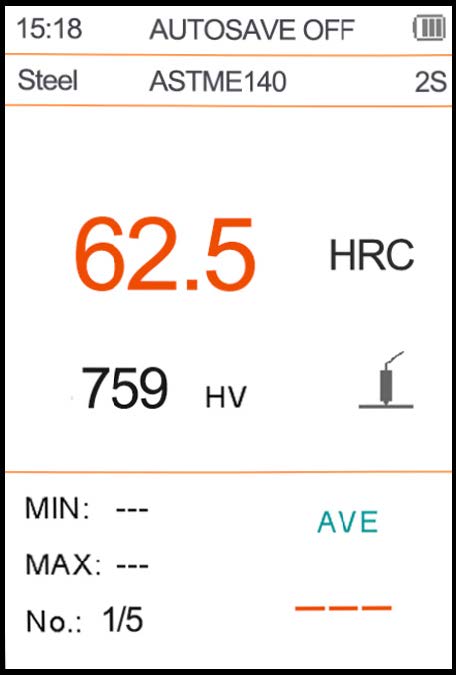

- Main test parameter: HV; Convertible parameters: HRC, HRA, HRB, HBW, etc

- Large-size screen directly displays current measurement value, cumulative measurement value, maximum value, minimum value, average value, and unit conversion value

- Small size and light weight, easy to carry, suitable for on-site measurement of large workpieces

- High measurement accuracy: ±4%HV, ±4%HB, ±1.5HR. The accuracy can reach ±3%HV when used with a measurement platform (optional).

- Small test indentation, little damage to the workpiece, belonging to micro-destructive/near non-destructive testing

- Fast measurement speed, with test results output in as fast as 1 second.

- Simple calibration: can store 5 groups of single-point calibration data, 1 group of default data, and 5 groups of multi-point calibration data in the instrument.

- Can store 50 groups of measurement data and 10 groups of calibration data sets.

- Single-point calibration is selected for materials with different elastic moduli, which is convenient and fast.

- For materials without clear conversion tables and unknown materials, any hardness scale can be selected for multi-point calibration to eliminate system errors caused by conversion tables.

- Any hardness scale can be customized in multi-point calibration mode.

- Can be connected to a Bluetooth printer (optional) to print measurement data or connected to a computer terminal to export measurement data.

- Executive standards: GB/T 34205; DIN 50159; ASTM-A1038; JB/T 9377; JJF 1436

Product Applications:

- On-machine inspection of parts in mechanical manufacturing to avoid errors caused by workpiece disassembly.

- Local hardness testing of aerospace and automotive parts (such as gear tooth surfaces, shaft surface hardened layers).

- Random hardness inspection of weld seams of special equipment and pressure vessels to ensure welding quality.

Technical Specifications

| Name | Ultrasonic Hardness Tester |

| Model | UHT-100 |

| Measurement Units and Ranges | HV 50~1599,HRC 20~68,HRB41~100,HRA 61~85.6,HB 85~650,HS 34.2~97.3,MPa 255~2180 |

| Test Accuracy | ±4%HV;±4%HB;±1.5HR |

| Resolution | 1HV;0.1HRC;0.1HB |

| Test Direction | Supports 360° measurement The indenter can measure when the angle with the measured surface is 90°±3°. |

| Battery Specification | Rechargeable battery, 3.6V, 3000mAh lithium battery |

| Battery Life | 10 hours |

| Operating Conditions | Temperature: -10℃~40℃ Humidity: not more than 90%RH No strong electromagnetic interference |

| Host Dimensions (mm) | 170*70*20 |

| Probe Dimensions (mm) | Φ22*150 |

| Weight | 650g |

Standard Configuration

| Name | Quantity |

| Host | 1 |

| Manual Probe (2kgf) | 1 |

| Probe Connecting Wire | 1 |

| 5V Charger | 1 |

| USB Cable | 1 |

| Standard Hardness Block | 1 |

| Protective Equipment Case | 1 |

| Calibration Certificate | 1 |

| Instruction Manual | 1 |

| Qualification Certificate | 1 |

| Warranty Card | 1 |

Optional Configuration

| Desktop Measurement Platform |

| Portable Measurement Platform |

| Bluetooth Printer |

| Probes (1kgf; 3kgf; 5kgf; 10kgf) |

최신 제품

최신 정밀 측정 솔루션

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- 그래니트 설정 도구

- 그래니트 설정 도구

- iVibra-6380 3축 진동 테스터

- MS602L Electronic Balance

- MS2003GH 전자 저울

- MS63B Electronic Balance

마지막으로 업데이트되었습니다: 2026-02-14

모든 신제품 보기