Polishing Cloth

Product Introduction:

- A series of metallographic polishing fabrics developed and produced specifically for rough and fine polishing during metallographic sample preparation. Suitable for various models and specifications of metallographic polishing machines both domestically and internationally, especially for semi-automatic or fully automatic metallographic polishing machines.

- The metallographic polishing fabric series consists of multiple layers such as polishing layer, storage abrasive layer, and protective layer, among which the most important layer is the polishing fabric layer that is truly used for polishing. This layer is made of high-quality fabrics with high strength, different pile lengths and textures, suitable for metallographic polishing. Thus, this polishing fabric has excellent polishing effect and a long service life.

Standard Delivery

Product Description:

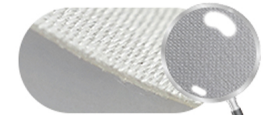

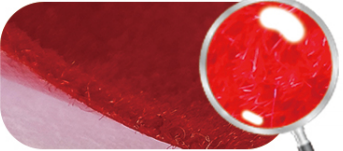

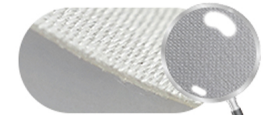

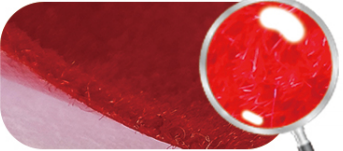

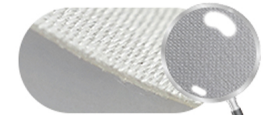

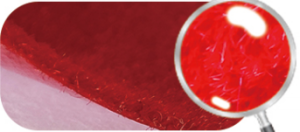

| Velvet: Long fluff silk, for stainless steel high precision material or aluminium, copper, magnesium soft material, for Diamond suspension: 0.5~5μm. |  |

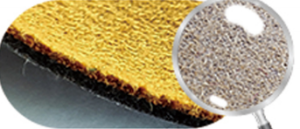

| Flocked: Short fluff cotton, for stainless steel,electronic circuit board,soft metal, for Diamond suspension: 1~3μm. |  |

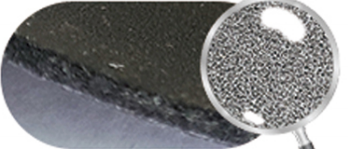

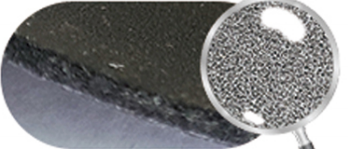

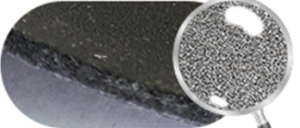

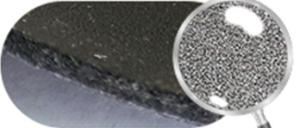

| Canvas: Without fluff cotton, for stainless steel rough polishing, for Diamond suspension: 5~14μm. |  |

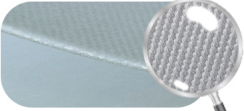

| Silk: Without fluff, for structures such as graphite or inclusions, for Diamond suspension: 0.5~3.5μm. |  |

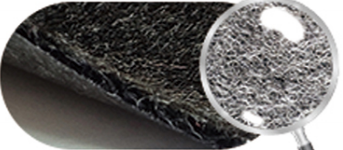

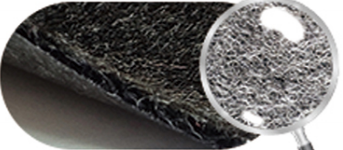

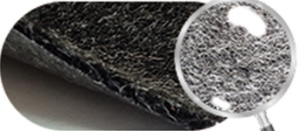

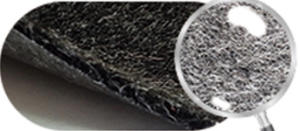

| Woollen: Thickened navy fabric, woolen pressed products, used for steel materials, for Diamond suspension: 3~5μm. |  |

| Nylon: Chemical fiber products, rough polishing of steel materials, for Diamond suspension: 7~20μm. |  |

Technical specification:

| Material:Velvet, Flocked, Silk, Woolen, Canvas,Nylon |

| Diameter(mm):Φ200/220/230/250/300mm |

| Packing: 10pcs/wrap |

| Adhesive: No/Yes |

Product Description:

|

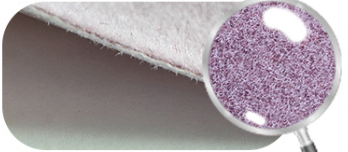

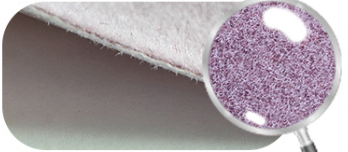

Synthetic fiber: Long nap, for all materials rough polishing, with 2.5~10μm Diamond or Aluminum Oxide . |

|

|

Synthetic fiber(flocked): For all materials rough polishing and Ceramics, crystals and other materials, with 1~3.5μm Diamond Suspension or Aluminum Oxide Suspension |

|

|

Woollen(pressing product): For all materials rough polishing, with 1~5um Diamond Suspension or Aluminum Oxide Suspension |

|

|

Cotton(with short fluff): For all materials rough polishing, with 1~3.5μm Diamond Suspension or Aluminum Oxide Suspension |

|

|

Chamois: Applied to non-ferrous metals, glass, silicon and other materials, with 0.05~3μm Diamond Suspension or Aluminum Oxide Suspension or Silicon Suspension |

|

|

High Precision Chemical Fiber Material: (Damping Fabric)Suitable for non-ferrous metals, glass, silicon, with 0.05~3μm Diamond Suspension or Aluminum Oxide Suspension or Silicon Suspension |

|

|

Cashmere: Suitable for iron, copper, magnesium and zinc, with 0.5~3.5μm Diamond Suspension or Aluminum Oxide Suspension |

|

|

Imported polished velvet: Suitable for non-ferrous metals, glass, silicon, with 0.05~3μm Diamond Suspension or Aluminum Oxide Suspension or Silicon Suspension |

|

|

Leather: Suitable for non-ferrous metals, glass, silicon, with 0.05~3μm Diamond Suspension or Aluminum Oxide Suspension or Silicon Suspension |

|

| Diameter(mm):Φ200/220/230/250/300mm(Can be customized, 3-1040mm) |

| Packing: 10pcs/wrap |

| Adhesive: No/Yes |

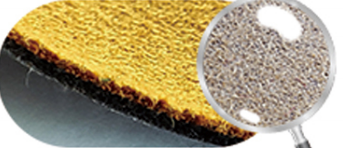

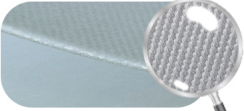

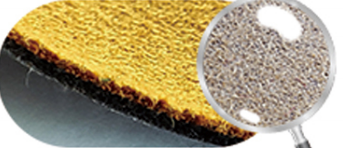

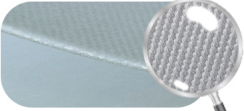

Synthetic Polymer Adhesive Polishing Cloth

|

Product Description: No-fluff, multi-void, used with Diamond, Alumina Oxide, Silicon dioxide suspensions(0.02~1μm), suitable for the final fine polishing (especially for simultaneous mechanical-chemical polishing) of a wide range of materials (especially very soft materials such as titanium, copper, silver, other non-ferrous metals, glass, silicon and other materials.) |

|

| Material: Synthetic Polymer |

| Diameter(mm):Φ200/220/230/250/300mm |

| Packing: 10pcs/wrap |

| Adhesive: No/Yes |

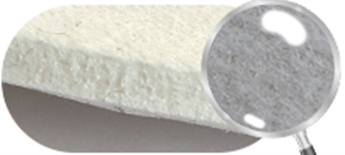

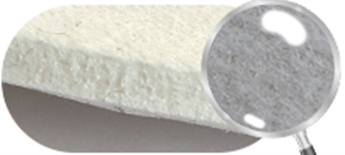

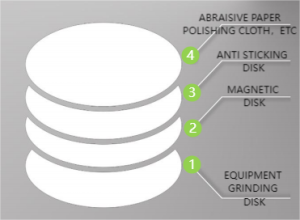

ASD Anti-stick Disk

| Features: The surface adopts a special anti stick coating, and adhesive sandpaper or polishing cloth can be pasted on this disk, making it easy to replace and leaving no residual adhesive. Can be reused. |  |

| Function: It can also have adhesive on the back, used to directly fix this disk to any grinding or polishing disk. |

|

Size:203/220/230/250/300mm |

|

Package: 5pcs/box |

MD Magnetic Disk

| Function Upper surface: with magnetism, connected by magnetism with anti sticking disk. |  |

| Function Lower surface: connected to aluminum or iron plates on polishing machines/pre-grinding machines with non drying adhesive. |

|

Size:203/220/230/250/300mm |

|

Package: 1pc/box |

Usage:

- Clean the surface of the aluminium/iron diskof the polishing machine of residual glue, oil, foreign matter, etc.;

- Use the adhesive backing on the lower surface of the magnetic diskto bond the magnetic diskto the aluminium/iron disk of the grinding and polishing machine.

- Use the self adhesive polishing cloth/abrasive paperto bond the polishing cloth/abrasive paperto the non-stick disk.

- If the polishing cloth or abrasive paperneeds to be replaced, remove the polishing cloth or abrasive paperfrom the anti-sticky disk through the notch of the anti-sticky disk.

- If the polishing cloth or abrasive papercan be used again, but need to change the abrasive papergrain size or the type of polishing cloth, remove the anti-adhesive disk (with polishing cloth or abrasive paper on it) from the notch of the magnetic disk, and replace it with another anti-adhesive disk (with other specifications of polishing cloth or abrasive paper on it).

최신 제품

최신 정밀 측정 솔루션

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- 그래니트 설정 도구

- 그래니트 설정 도구

- iVibra-6380 3축 진동 테스터

- MS602L Electronic Balance

- MS2003GH 전자 저울

- MS63B Electronic Balance

마지막으로 업데이트되었습니다: 2026-02-14

모든 신제품 보기