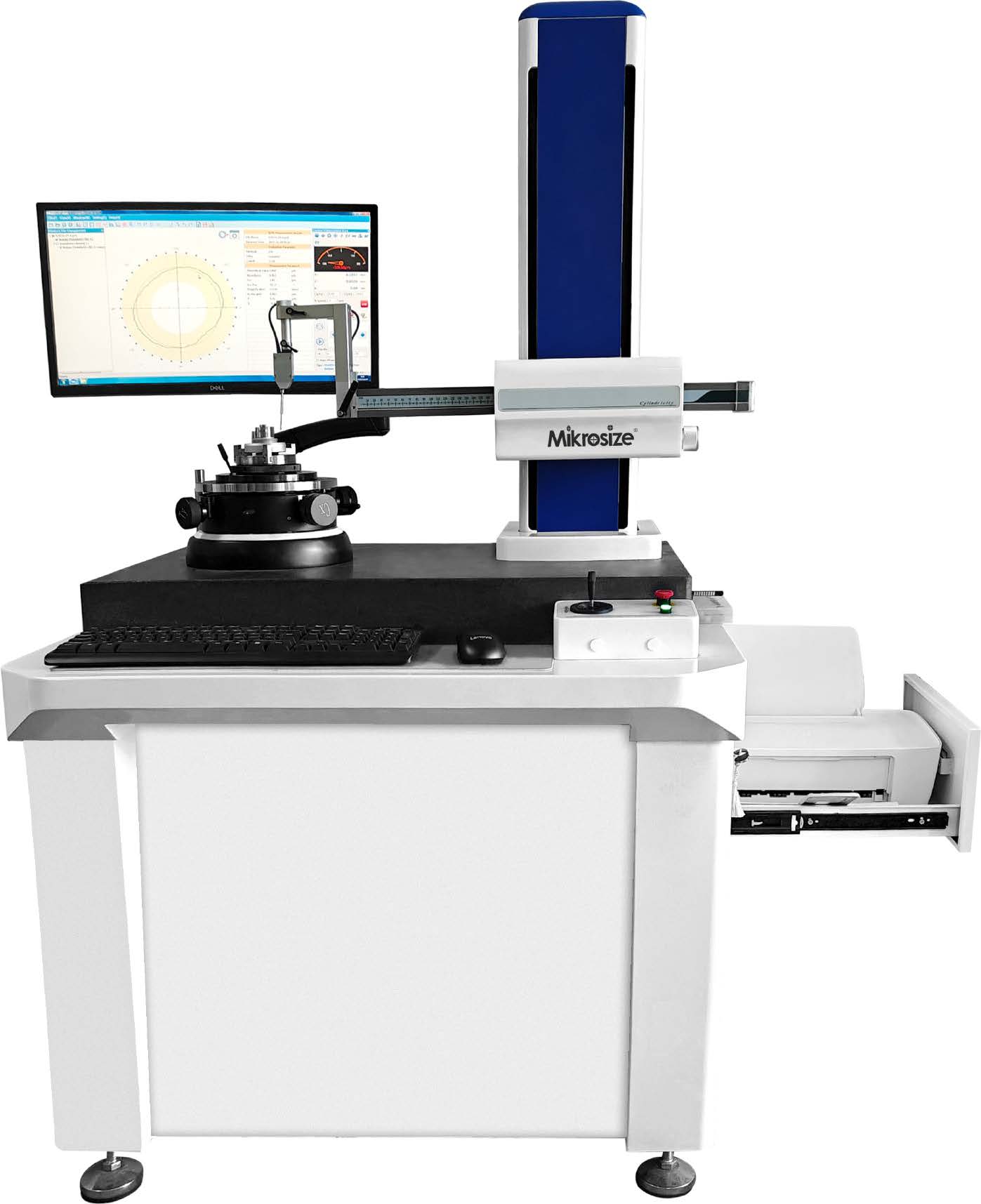

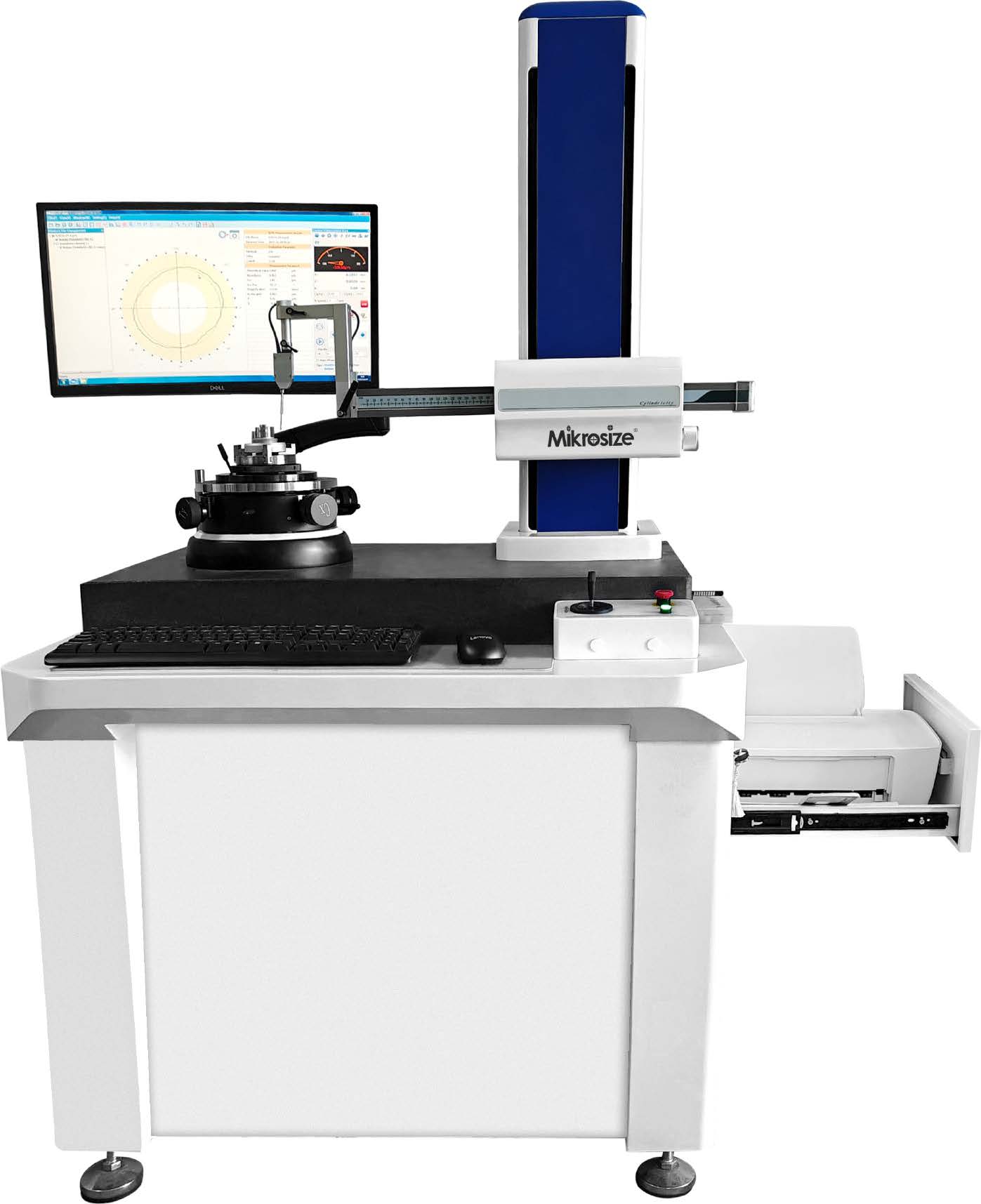

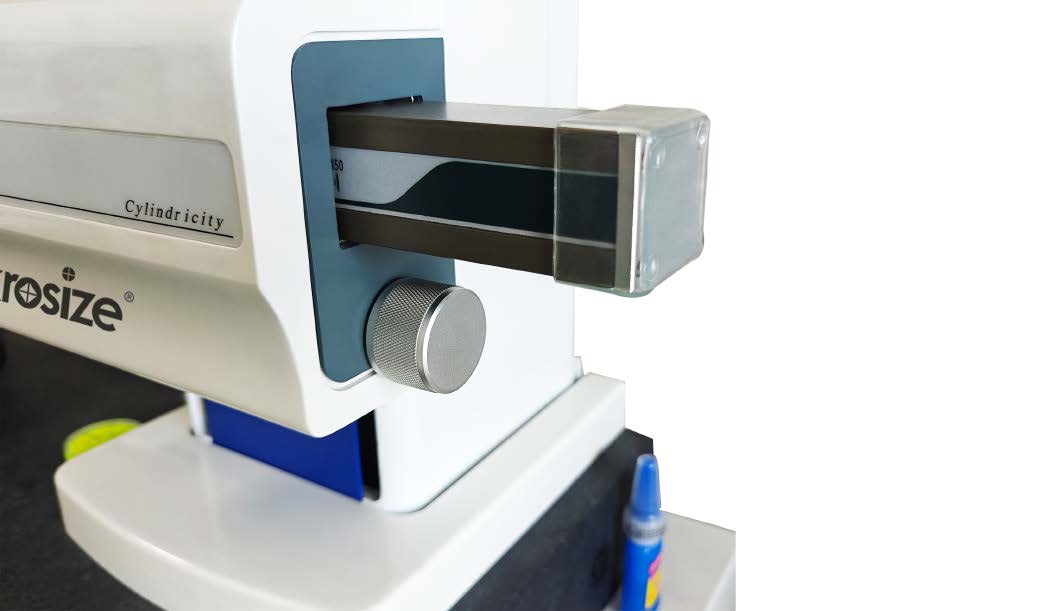

MRC-300M/400M/500M/500A 진원도 및 원통도 측정기

Video Demonstration

Product Features & Applications

Product Feature:

- Adopts high-precision aerostatic spindle as the reference, which is wear-free and maintains long-term accuracy.

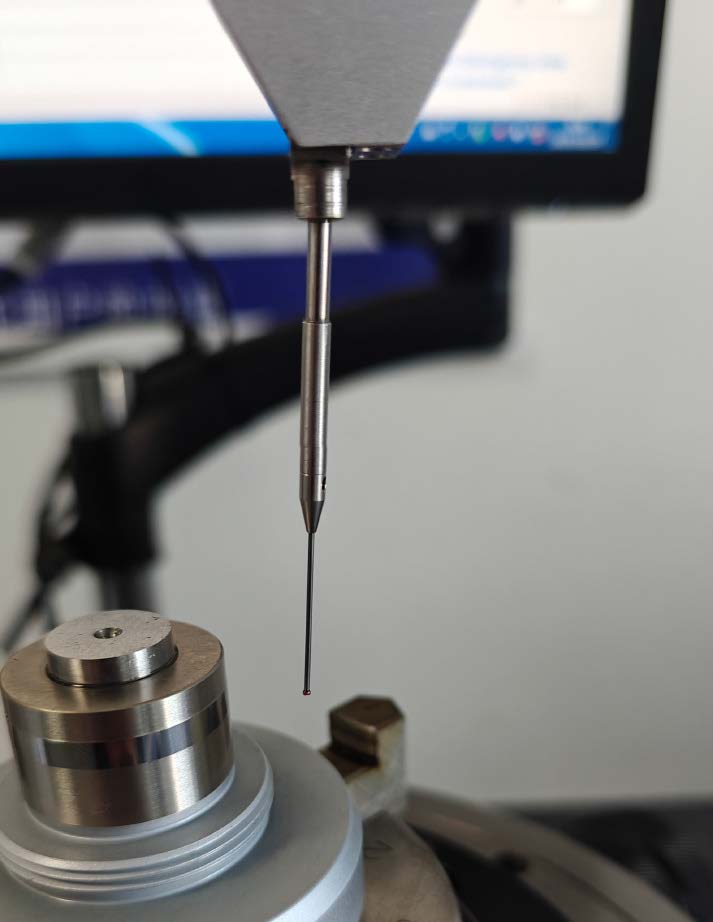

- Uses the radius measurement method with workpiece rotation.

- Can measure roundness, cylindricity, straightness, runout, total runout, taper, diameter, concentricity, coaxiality, flatness, parallelism, perpendicularity, eccentricity and other parameters of various regular and irregular annular workpieces.

- Can analyze surface waviness (Wc, Wp, Wv, Wt, Wa, Wq), conduct spectrum analysis and wave height analysis.

- Can measure the cross-sectional ellipticity and longitudinal profile of piston outer circles (optional).

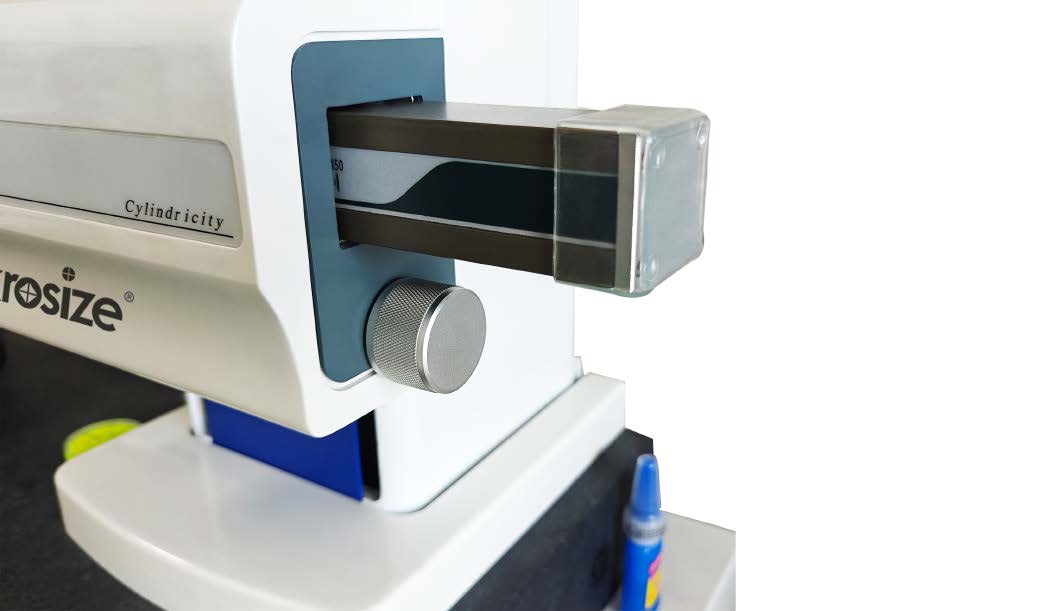

- Column stroke options include 400/500/700mm, with support for customization of larger strokes.

- Self-centering and leveling worktable, available in manual or automatic versions.

- The spindle can bear 30kg, and customization for larger loads is supported.

- Equipped with an air filter as standard.

- Four roundness evaluation methods: Minimum Zone Method, Least Squares Method, Minimum Circumscribed Circle Method, Maximum Inscribed Circle Method.

- Roundness filter ranges: 1-500, 1-150, 1-50, 1-15, 15-500.

- Waviness filter ranges: 3-16, 17-100.

- Data collection uses imported precision circular gratings with an accuracy of up to 0.0125μm, collecting 14,400 points per circle, ensuring high accuracy and stability.

- The measurement software is a CA system-based software running on Windows operating systems, supporting WinXP, Win7, Win10 and Win11.

- Partial arcs can also be measured and processed.

- Automatically identifies contour interruptions, and has the function of automatically or manually eliminating gaps and abnormal points.

- SPC statistical analysis: conducts statistical analysis on a large number of measurement data and provides graphical analysis reports.

- Can set process requirements to judge measurement parameters, improving the visibility of quality control.

- Supports single or multiple measurement data printing on the same page.

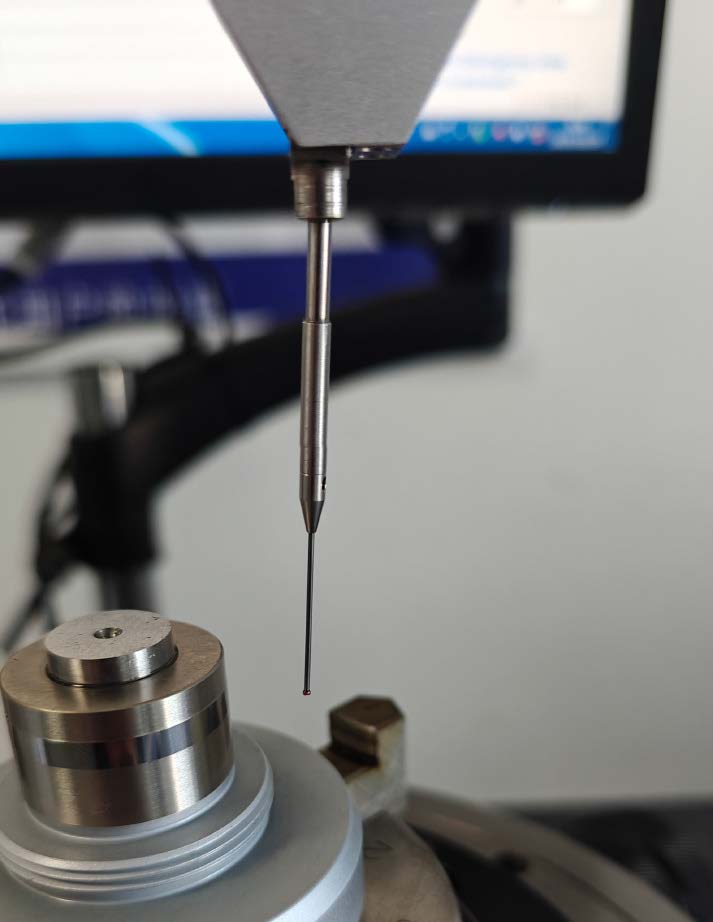

- Equipped with a Φ2mm ruby probe as standard; ruby probes of different specifications can be optionally configured.

- Complies with industry standards such as JJG 429, ISO 1101 and ISO 12180.

Product Application:

- Automobile manufacturing

Inspects core components such as engine crankshafts, camshafts, piston pins, and bearing inner/outer rings to ensure power transmission accuracy and assembly tightness.

- Aerospace

Verifies key components such as aircraft engine blade shafts, hydraulic system valve cores, and turbine shafts to meet precision requirements under extreme working conditions.

- Bearing/seal industry

Batch inspects bearing rolling elements, seal ring grooves and other components to ensure rotation accuracy and sealing performance.

Technical Specifications

| Item | Roundness and Cylindricity Measuring Instrument | |||||

| Model | MRC-300M | MRC-400M | MRC-500M | MRC-500M | ||

| Measurement Range | Maximum workpiece rotation diameter | 320mm | 420mm | |||

| Maximum measurement diameter | 270mm | 370mm | ||||

| Maximum measurement height | 300mm | 400mm | 500mm | 500mm | ||

| Maximum measurement depth | 100mm(determined by probe rod length) | |||||

| Maximum load-bearing capacity | 25kg | 40kg | 60kg | 30kg | ||

| Aerostatic Spindle Accuracy | Radial error | (0.025+4H/10000)μm H: Measurement height from the platform | ||||

| Axial error | (0.025+4X/10000)μmX: Measurement radius | |||||

| Worktable | Table diameter | Φ200mm | Φ280mm | |||

| Adjustment range | Eccentricity adjustment: ±3mm; Level adjustment: ±1° | |||||

| Adjustment method | Manual | Automatic | ||||

| Rotation speed | 0~12rpm | |||||

| Straightness | 0.3μm/100mm | 0.2μm/100mm | ||||

| Grating | Column grating resolution (optional) | 0.05/0.1/0.5/1μm | ||||

| Horizontal guide rail grating resolution (optional) | 0.05/0.1/0.5/1μm | |||||

| Parallelism between Spindle and Z-axis | 1.5μm/300mm | 2μm/400mm | 2.5μm/500mm | 2.5μm/500mm | ||

| Horizontal Stroke | 250mm | 250mm | 270mm | 270mm | ||

| Sensor | Measuring range | ±500μm | ||||

| Resolution | 0.005μm | |||||

| Probe shape | Φ2mm ruby ball probe(Φ1mm、Φ0.5mmprobes optional) | |||||

| Measuring force | 1~12g | |||||

| Data Collection | Imported grating, 14,400 points/circle | |||||

| Magnification | Arbitrary up to 200,000x maximum | |||||

| Optional modules | Bearing waviness/harmonic analysis/RTA spectrum analysis | |||||

| Air supply pressure | 0.45~0.8Mpa | |||||

| Air supply flow rate | ≥0.2 m³/min | |||||

| Power supply | AC 220V±10% 50Hz | |||||

| Environmental requirements | Temperature (T):10~30℃; Relative humidity (RH):<85% | |||||

| Product dimensions (L*W*H) | 960*650*1550mm | |||||

| Packaging dimensions (L*W*H) | 1000*750*1650mm | |||||

| Product weight | 240kg | |||||

| Total packaging weight | 290kg | |||||

Standard Configuration

| Name | Quantity |

| Roundness and cylindricity measuring instrument | 1 set |

| Self-centering and leveling worktable | 1 set |

| Precision three-jaw chuck | 1 piece |

| Air filtration system | 1 piece |

| Computer | 1 unit |

| Printer | 1 unit |

| Measurement software | 1 set |

| Ellipse standard part | 1 piece |

| Cylinder standard part | 1 piece |

| Φ2mm ruby probe | 1 piece |

| Qualification Certificate | 1 copy |

| Warranty Card | 1 copy |

| Calibration Certificate | 1 copy |

| Instruction Manual | 1 copy |

Optional Configuration

| 3D adjustment table |

| Quick centering tooling |

| Centering tooling |

| Steel ball fixture |

| Other standard parts |

| Other probes |

최신 제품

최신 정밀 측정 솔루션

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- 그래니트 설정 도구

- 그래니트 설정 도구

- iVibra-6380 3축 진동 테스터

- MS602L Electronic Balance

- MS2003GH 전자 저울

- MS63B Electronic Balance

마지막으로 업데이트되었습니다: 2026-02-14

모든 신제품 보기