iProjec-H12/H16/H24 Horizontal Measuring Profile Projector

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Product Features & Applications

Product Feature:

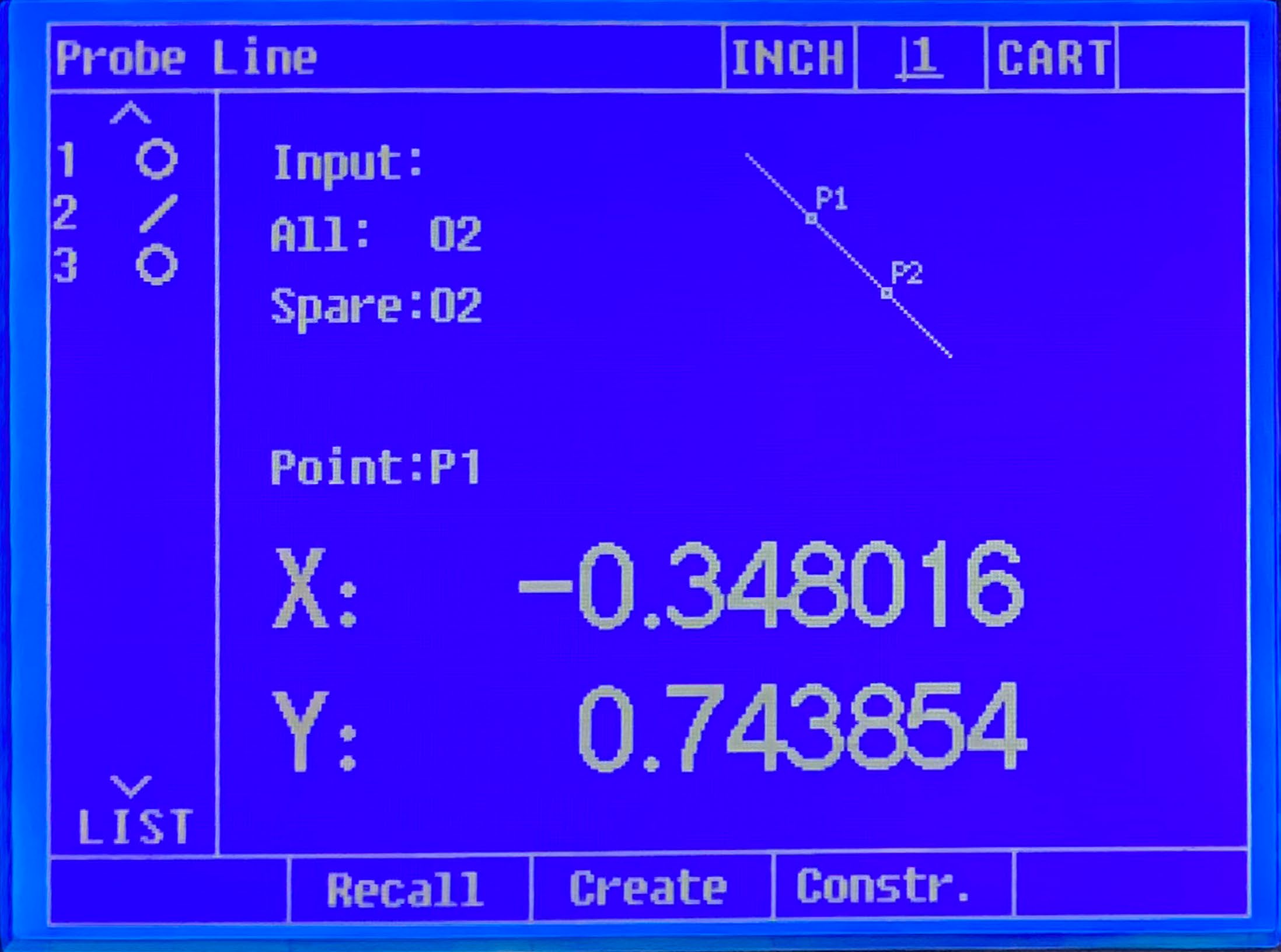

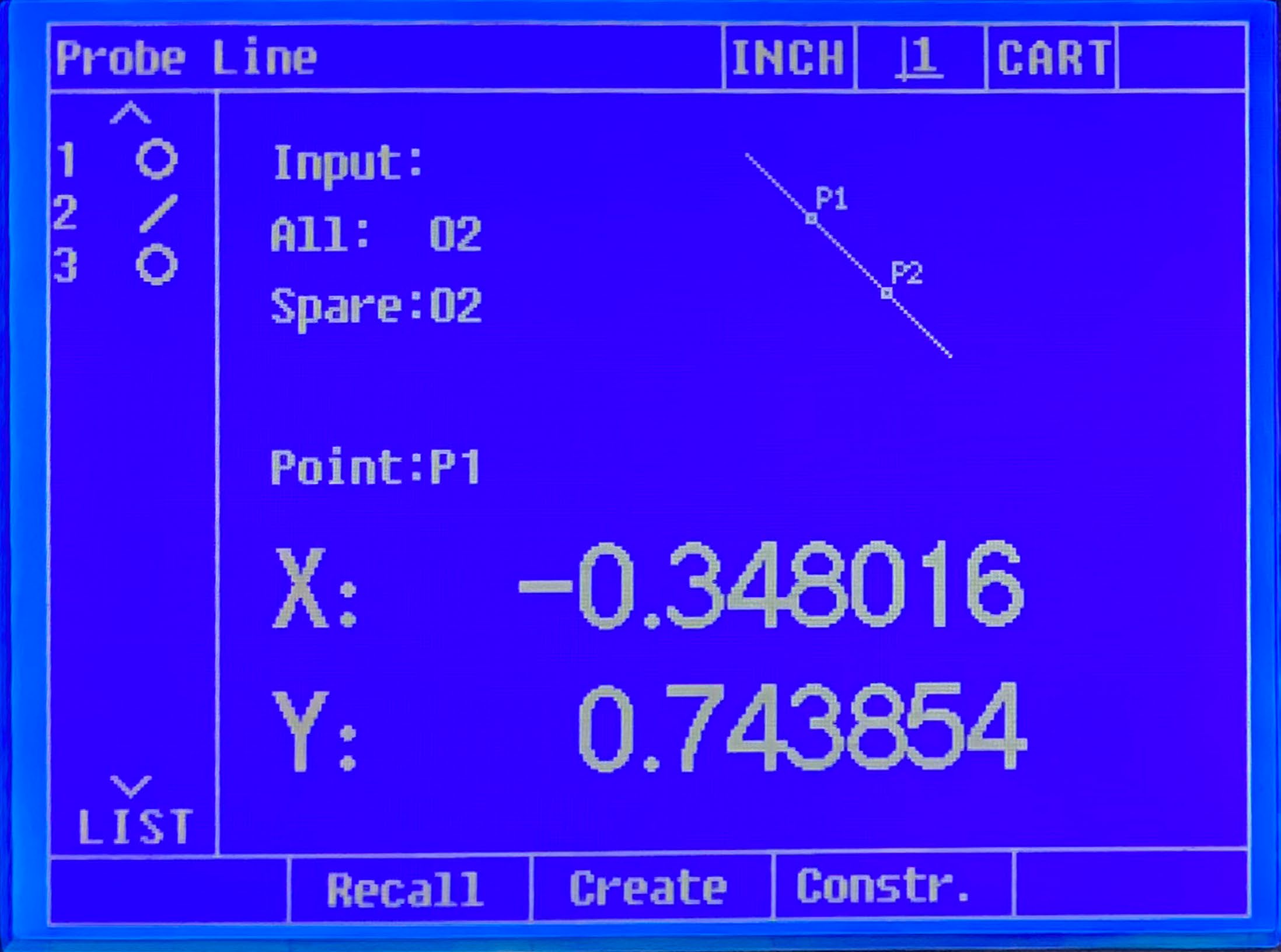

- High-precision optical system: Equipped with high-quality objective lenses, it can produce sharp and clear images, and the magnification ratio is accurate, ensuring the accuracy of dimensional measurement and meeting the requirements of precise measurement.

- Precision worktable: Processed from aviation aluminum alloy, it has a large measurement range and is lightweight. The digital display resolution of the X and Y coordinates reaches 0.0005mm, and the positioning accuracy is extremely high.

- Stable guide rail transmission: The lifting transmission of the worktable adopts imported V-shaped linear guide rails, which run smoothly, reduce vibration deviation, and ensure the stability and accuracy during the measurement process.

- Sturdy and durable structure: The overall structure has strong versatility, a reasonable design, and high-quality materials. It is resistant to interference and wear, and can maintain high precision even after long-term use.

- Advanced digital display system: The coordinate indication value error is ≤3+L/200. Equipped with an advanced digital display system, the readings are intuitive and accurate, effectively improving the measurement accuracy and efficiency.

Product Application:

- Mechanical manufacturing: It can accurately measure complex mechanical parts, such as the contours of cams and gears, ensuring the machining accuracy and assembly quality.

- Electronic industry: It can accurately detect the dimensions of tiny electronic components, facilitating the miniaturization and high-precision production of electronic products.

- Instrument production: It can measure the components of instruments efficiently, ensuring the stable and reliable assembly and performance of the instruments.

- Mold processing: It is used for the measurement of key parts such as mold cavities, improving the precision of mold manufacturing.

- Metrological verification: It provides a high – precision measurement basis for metrological departments, ensuring the accurate transfer of measurement values.

Latest Products

Our newest precision measurement solutions

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- Granite Set-up Tools

- Granite Set-up Tools

- iVibra-6380 3-Axis Vibration Tester

- MS602L Electronic Balance

- MS2003GH Electronic Balance

- MS63B Electronic Balance

Last updated: 2026-02-14

View All New ProductsContact Us

Get in touch for product information, quotes, or technical support

Call us

+86-0553-2836939

Email us

mikrosize@mikrosize.com