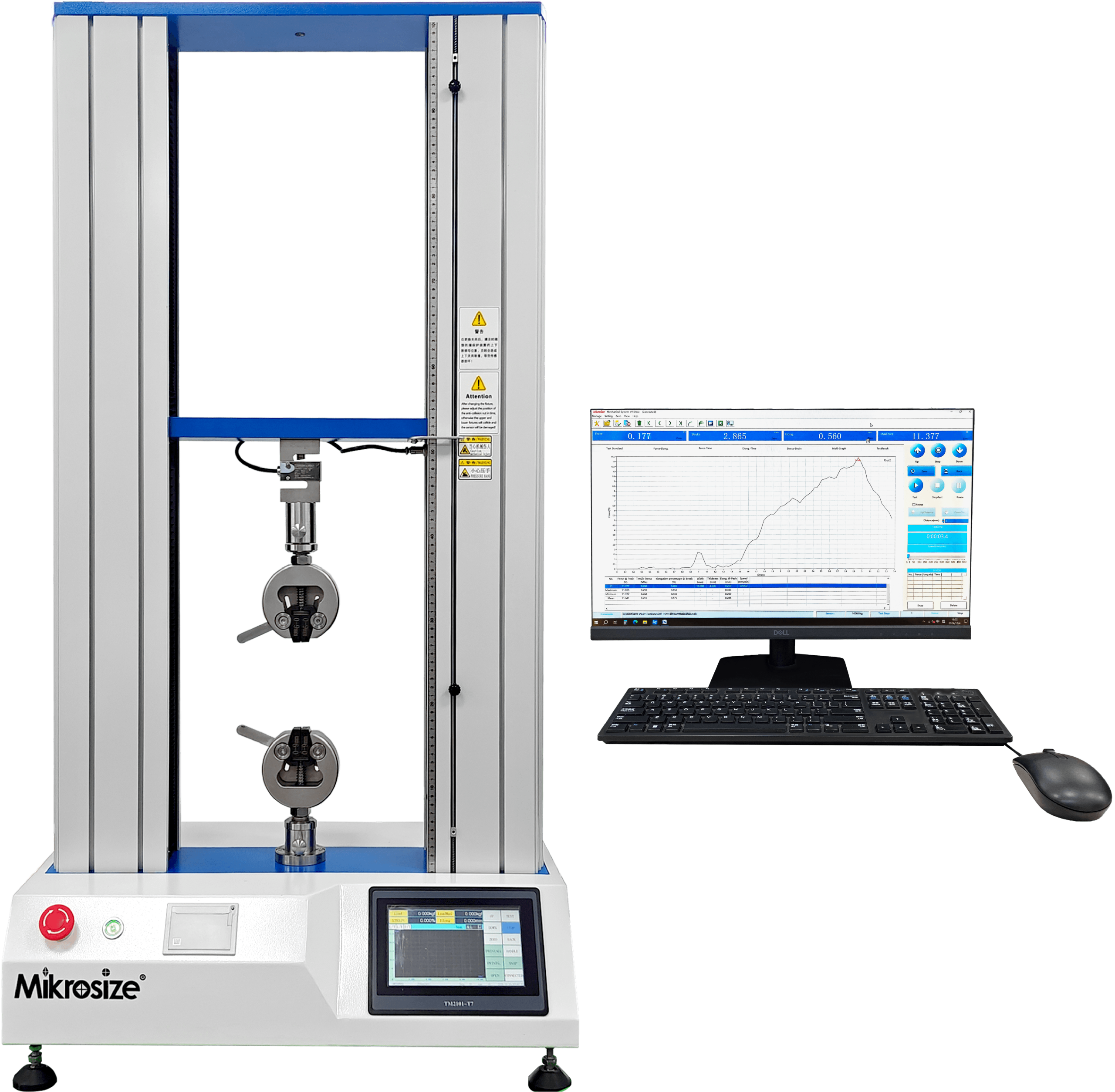

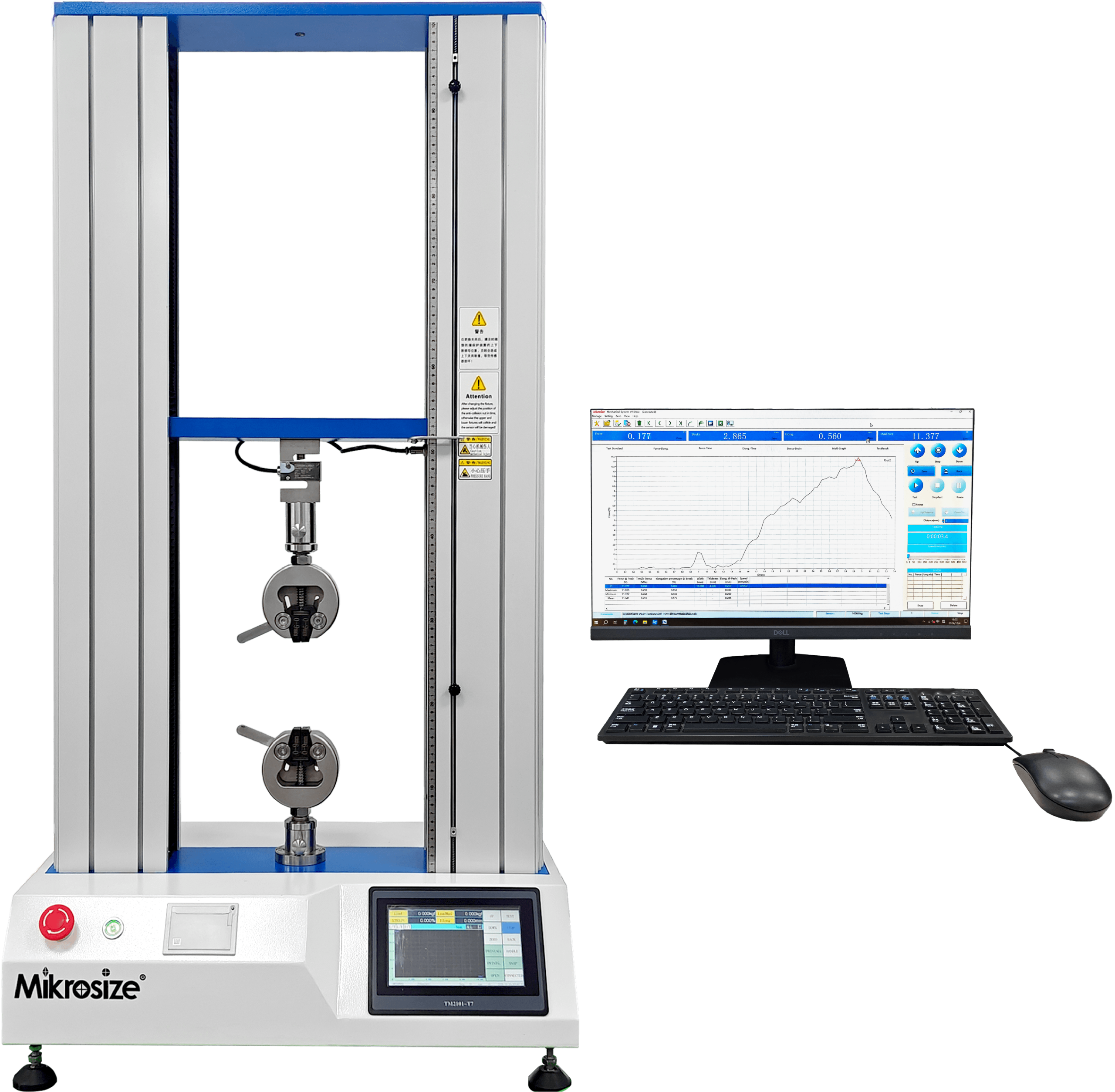

UTM-TDC Dual – Column Universal Material Testing Machine (Bench Type)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

.jpg)

Video Demonstration

Product Features & Applications

Product Feature:

- Color touch – screen for easy and convenient operation.

- Can be connected to computer and used with software for more functions.

- Driven by a stepper motor.

- Class 1 testing machine.

- C3 – grade high – precision load cell.

- Gantry – type dual – column high – rigidity design for durability.

- Maximum capacity: 10KN.

- Test speed:

Maximum 500mm/min,

Minimum 0.1mm/min

- Multiple units available:

Force: g、Kg、lb、N、KN

Displacement:inch、 cm 、 mm

- With the function of automatically returning to the initial position

- after the test.

- In addition to the standard tensile fixture, other types of fixtures

- can be customized.

- The software provides curve graphs, data tables, and test

- reports, all of which can be printed.

- Automatically calculates maximum force, minimum force, average

- force, maximum deformation, elongation rate, strength, etc.

- With multiple curve modes such as stress – strain, force -displacement, force – time, and strength – time.

- With test mode functions for tension, bending, compression,tearing, peeling, elongation rate, etc.

- Equipped with multiple protection devices including mechanical travel switches, emergency stop switches, overload limit protection,and break – point stop protection.

- Standards complied with:

GB/T 2611、GB/T 16491、GB/T 1040、ISO 527、GB/T 8804、GB/T 9341、GB/T 12160、GB/T 16825

Product Application:

- Manufacturing industry: Used to test the mechanical properties of various parts and raw materials to ensure product quality meets design requirements.

- Material research and development: Helps researchers understand the mechanical properties of new materials and provides data support for material improvement and innovation.

- Research institutions: In scientific research experiments, it is used to study the mechanical behavior laws of substances and promote the development of related disciplines

- In the process of mechanical processing, Brinell hardness tester can be used to detect the hardness of raw materials, in order to select suitable processing technology and cutting tools.

- Can be used to test the hardness of mechanical components such as gears, bearings, bolts, etc., to ensure that they meet design requirements and performance requirements.

- Can be used to test the hardness of forgings to determine the effectiveness of forging processes and the quality of forgings.

Technical Specifications

|

Model |

UTM-TDC |

||||||||

|

Name |

Dual - Column Universal Material Testing Machine (Bench Type) |

||||||||

|

Capacity |

KN |

0.05 |

0.1 |

0.2 |

0.5 |

1 |

2 |

5 |

10 |

|

KG |

5 |

10 |

20 |

50 |

100 |

200 |

500 |

1000 |

|

|

lb |

11 |

22 |

44 |

110 |

220 |

440 |

1102 |

2204 |

|

|

Testing Machine Class |

Class 1 |

||||||||

|

Force Unit |

g、Kg、lb、N、KN |

||||||||

|

Displacement Unit |

Inch、cm、mm |

||||||||

|

Effective Test Force |

0.4%~100%FS |

||||||||

|

Force Accuracy |

Within ±1% of Indication Value |

||||||||

|

Force Resolution |

1/300000 |

||||||||

|

Displacement Accuracy |

Within ±1% of Indication Value |

||||||||

|

Displacement Resolution |

0.001mm |

||||||||

|

Deformation Measurement Range |

2%~100%FS |

||||||||

|

Deformation Indication Accuracy |

Within ±1% of the indicated value |

||||||||

|

Maximum Test Speed |

500mm/min |

||||||||

|

Minimum Test Speed |

0.1mm/min |

||||||||

|

Speed Accuracy |

Within ±1% of the indicated value |

||||||||

|

Crossbeam Stroke |

No - fixture test stroke: 920mm |

||||||||

|

Measuring Width |

320mm |

||||||||

|

Fixture Configuration |

Configured according to customer requirements |

||||||||

|

Return Method |

Manual, Automatic |

||||||||

|

Stop Method |

Automatically stop at the maximum fracture value. Stop when the upper and lower limit safety settings are reached. |

||||||||

|

Safety Device |

Mechanical travel switch protection. Emergency stop switch for emergency braking. |

||||||||

|

Overload Protection |

When reaching 100% of the maximum load, the machine automatically stops for protection |

||||||||

|

Power Supply Voltage |

(Can be selected as 110V.AC/60Hz according to the country) |

||||||||

|

Machine Size/Weight |

L*W*H:650mm*400mm*1220mm About 70Kg |

||||||||

|

Packaging Size/Weight |

L*W*H:700mm*450mm*1350mm About 90Kg |

||||||||

Standard Configuration

|

Name |

Quantity |

|

Machine Mainframe |

1 |

|

Tensile Fixture |

1 |

|

Testing Software |

1 |

|

Power Cord |

1 |

|

Computer Connection Cable |

1 |

|

说明书Instruction Manual |

1 |

|

Certificate of Conformity |

1 |

Optional Configuration

|

Other types or customized fixtures |

|

Computer |

|

Protective cover |

Latest Products

Our newest precision measurement solutions

- MS-500 Portable Electronic Microscope

- Bench Center With Straightness Measurement

- MS-XRF350 Multi-functional Coating Thickness Measuring XRF Spectrometer Technical Specification

- TST-64/80/100/150 Thermal Shock Test Chamber

- Granite Set-up Tools

- Granite Set-up Tools

- iVibra-6380 3-Axis Vibration Tester

- MS602L Electronic Balance

- MS2003GH Electronic Balance

- MS63B Electronic Balance

Last updated: 2026-02-14

View All New ProductsContact Us

Get in touch for product information, quotes, or technical support